Detroit, Michigan — A recent I-CAR U.S. Repairers Realm episode, along with supplementary material from Ford’s most recent On Target newsletter, sheds light on why some OEM replacement parts may not fit the same as the original part removed from the vehicle.

Gerry Bonanni, senior damageability engineer for Ford, and Stellantis’ Body Collision Lead Lynn Rogers recently joined I-CAR U.S. technicians Bud Center, Scot VanHulle and Jason Hauboldt to discuss variations that can be found in OEM service parts.

Center pointed out that challenges noted by technicians include panel parts that may not have guide holes or markets in the same locations they appear in on the productional panel they are repairing or replacing. VanHulle echoed the sentiment, saying that, depending on the OEM, discrepancies may not be noted in repair information.

Bonanni pointed out that, for Ford, this is referred to as an extraction point: when a part is removed from tooling and the production line with the intent to be used as a replacement service part. The variation occurs because certain guide holes and other markers are pierced into the vehicle structure as part of its run on the assembly line after the extraction point for a particular part has occurred. The piercing operations are done when the vehicle is a completed body, just before the e-coat process.

For example, Bonanni explained that grille opening reinforcement guide holes or apron attachment guide holes are pierced only after the body has been assembled to obtain together tolerances, which he said helps align bodylines. Because of this, repair technicians will need to cut new guide holes.

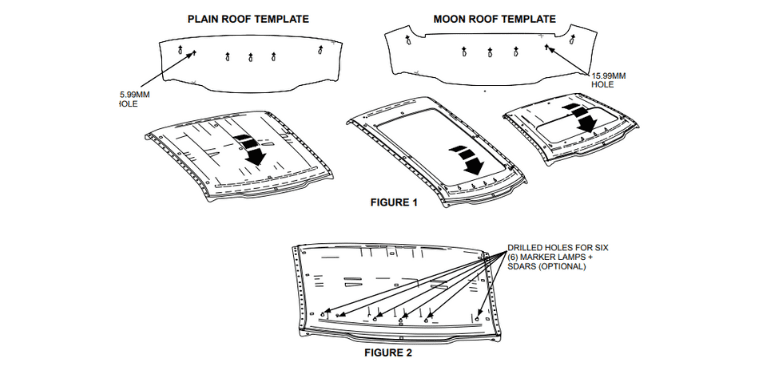

“Commonly, if we have that situation, we include an instruction sheet, which tells the technician where to cut [and] how to modify the part,” said Bonanni in the latest Ford On Target newsletter.

He added that some service parts templates are also available; emblem holes and moulding holes may require a template, he said.

“What I learned very, very early in my career is that the bodyman has to go in and utilize templates as they see fit.”

During the Repairers Realm episode, Rogers of Stellantis specified a similar case on a 2018 Jeep Cherokee in for outer wheelhouse and fuel fill reinforcement. In this case, the fuel door reinforcement was “a little bit different” than the one the technicians removed.

“It was narrower in the way it’s stamped,” Rogers explained. “There could’ve been a plethora of reasons for that to happen over time. In this particular case…we came up with a process and used some material from the original wheelhouse. We were able to get through that.”

“These kinds of things happen. We don’t necessarily see a lot of these things come through, we understand the position the shop is in to get the repair done properly and back out to the customer…I would ask that any shop that runs into an issue like this, we’ll help you through it.”

Click here to read more in Ford’s On Target newsletter, or here to view the Repairers Realm episode.

The post Navigating Variations: Ford shares insights on OEM part fitment issues in latest On Target newsletter appeared first on Collision Repair Magazine.